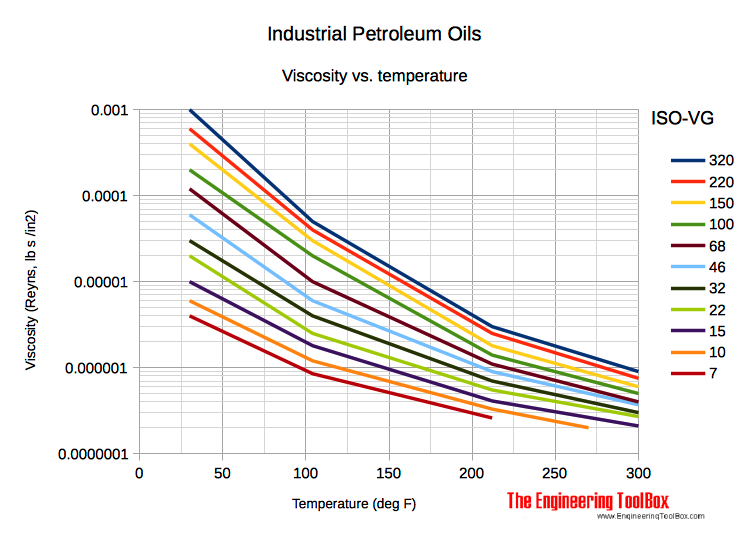

Using lubricants with viscosities in excess of those needed may generate excess heat and actually work against operators. The information in this figure is per common rule of thumb, using average viscosity improvers.

#Sae oil viscosity chart for f iso

Alternatively, the user might choose ISO VG 68 and verify that its operating temperature does not exceed 100 C (212 F). If the user selects ISO VG 32, he or she might start the pump and verify that its oil temperature had leveled off at no greater than 75 C.

Users enter the vertical scale near 9 cSt and move toward the right, where the line intersects with oils ranging from ISO VG 22 through ISO VG 320. For a required viscosity (vertical scale), the permissible bearing operating temperatures (horizontal scale) increase as thicker oils are chosen (diagonal lines). If users choose premium grade synthetic oils, they will enjoy a sizeable safety factor in lube applications.įigure 3. Note that Figures 2 and 3 were drawn years ago and apply to mineral oils. Unnecessarily viscous oils will become hot. The operating temperature derives its combined thermal input from bearing load and lube oil frictional drag. Note that a bearing's operating temperature must be known to determine what ISO VG is needed.

In this instance, one could operate with a lubricant which, at the bearing operating temperature, is somewhere between 8 and 9 cSt. To simplify, consider it 100 mm, and travel up from 100 to a location midway between the 3,000 and 5,000 rpm lines in Figure 2. The bearing's mean diameter would be 105 mm. (Courtesy of SKF)įor another example, if a bearing was mounted on a 70-mm shaft rotating at 3,600 rpm, we might assume that the bearing's outside diameter (OD) is twice its inner diameter (ID), or 140 mm. 3 A bearing with a mean diameter of 390 mm at a shaft speed of 500 r/min will require v 1= 13.2 cSt. Required minimum (rated) viscosity v 1 as a function of bearing dimension and shaft speed. Oil overheating may be an additional concern.įigure 2.

Oil rings, if used, would probably slow down and malfunction in such viscous oils. But that is unrealistically thick for most process pump bearings. The MRC Engineer's Handbook states, "In general, the oil viscosity should be about 100 Saybolt Universal Seconds (SUS) at the operating temperature." 1 If for some reason a bearing was operating at 210 degrees F, Figure 1 would call for a lubricant with an International Organization for Standardization (ISO) viscosity grade (VG) somewhere between 220 and 320. Whatever the user chooses, he or she must guard against using the thinnest oil found on the market to avoid the problem of inadequate oil film strength and thickness. They can use a jet of oil (oil spray) or convey the oil mixed with compressed air in the form of an oil fog-also called oil mist. Users can heat the oil or avoid oil rings and other risk-inducing lube application methods by using smarter means. Thick oils are more viscous and may not readily flow into the bearings. Figure 1 illustrates where these motor oils fit in comparison to the industrial oil designations used today. But thinner oils, perhaps SAE 10, can help prepare a vehicle for winter driving. Some will know from their experience with automobiles that thicker oils, such as Society of Automotive Engineers (SAE) 30, are more appropriate for warm summer months.

0 kommentar(er)

0 kommentar(er)